CNC Process Products

Now utilizing CNC machining technology, To perform more precise and accurate computing technology, Just like the history of industrial development, Can only rely on human to actually measure, Cutting….work process in the past time. SHANG ZHUN GEAR adopt Efficiency and Quality to obtain more Scientific Technology! ultra-highly automated production can be carried out in a more precise and faster manner.

CNC(Computer numerical control), full name are Computer Numerical Control, It is a computer-aided production method, Manufacturing through digital means, Make the production process more precise and efficient, Improve production quality that is difficult to achieve during manual manufacturing , It plays an important role in the manufacturing process of the Printing Machinery components.

CNC Processing Products ability to manufacture parts to very tight tolerances, The so-called tolerance refers to the error range of products allowed by relevant regulations.

Materials include metals and metal alloys. Ex. Aluminum alloy, steel alloy, brass, etc. according to different characteristics of materials for choose the right knife tool, Running speed, Material conveying speed, Coolant dose, Design manufacturing process. This makes CNC machining technology widely used in SHANG ZHUN GEAR. Those who rely on CNC processing technology include: Aerospace technology to the Sporting goods manufacturing.

Process and manufacture of materials from different angles. The more dimensions there are, the wider the direction in which the machine can operate during manufacturing, and the more precise the printing machinery and die-cutting machinery components produced will be.。

CNC machining is a method of subtractive manufacturing. The So-called subtractive manufacturing, as the name suggests, is to use the method of reducing raw materials to process the raw materials into the Printing Machinery parts or any mechanical Gear products.

Processed products

Printing Machinery/Component Processing

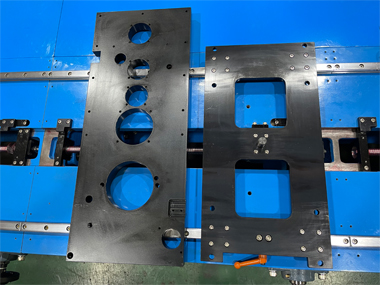

Left : Siding of the Printing station Right : Base plate of the Printing base

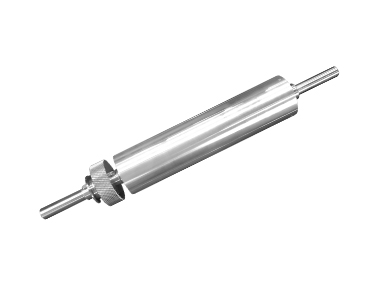

The Cylinder of the Full Rotary Letterpress Printing Machinery for the SANKI Machinery in the Japan.

The Cylinder of the Full Rotary Letterpress Printing Machinery for the SANKI Machinery in the Japan.

Distributing for bearing seat

The transmission Gears of the Printing station

The transmission Belt gear

Printing, Die-Cutting, Slitting Machinery/Component processing

The side panels on both sides with ink trough base for Print station.

Touch plate ring/ Printing Rubber roller seat

Printing Machinery Parts processing

Use CNC Processing to Compete in Cost components and Agile & Intelligent Operations to create the largest Printing Machinery Supply Chain.

SHANG ZHUN GEAR All Solutions for Completely From Mastering Agile Smart To 6 Challenges Market for Mechanical Components

Mall quantity and High demand

Diversification

Diversification

The Production schedule is more optimized, the number of the Mold changes and line changes is reduced, and the Waste caused by errors at each stage is reduced, thereby improving production efficiency, because the information from Orders, Procurement to Production can be consistent and Real-Time.

Short delivery time

Emergency Insert New Order schedule

Rely on experience

Energy saving and Carbon reduction

SHANG ZHUN GEAR CO., LTD.

We will strive to provide excellent manufacturing services for worldwide customers and establish mutually beneficial, long-term partnership. We will spread dedication to quality to every facet of the company and achieve a culture of continuous improvement to assure customer satisfaction. There is only one ultimate goal:

Carry forward the brilliance of 100% M.I.T. processing products around the World.